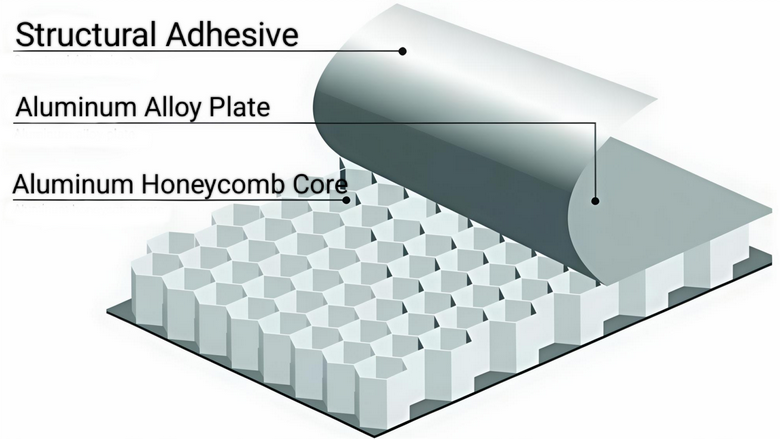

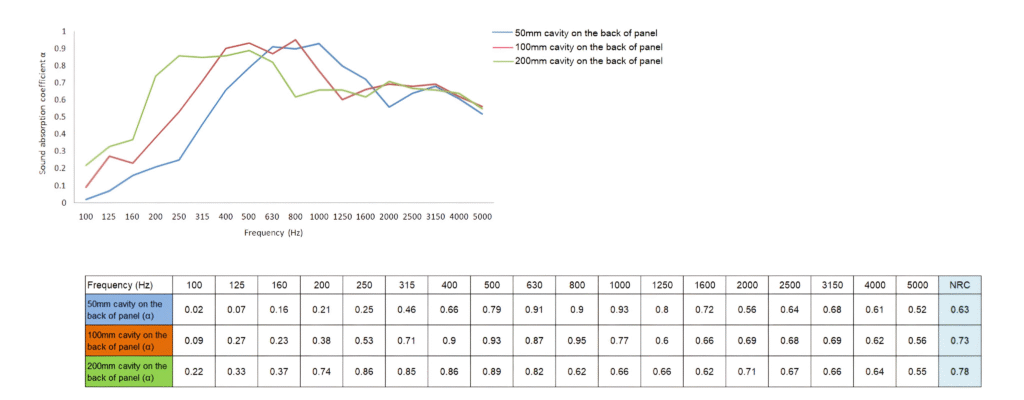

The ultra micro-perforated aluminum panel structure is an improvement on the micro-perforated sound-absorbing structure:

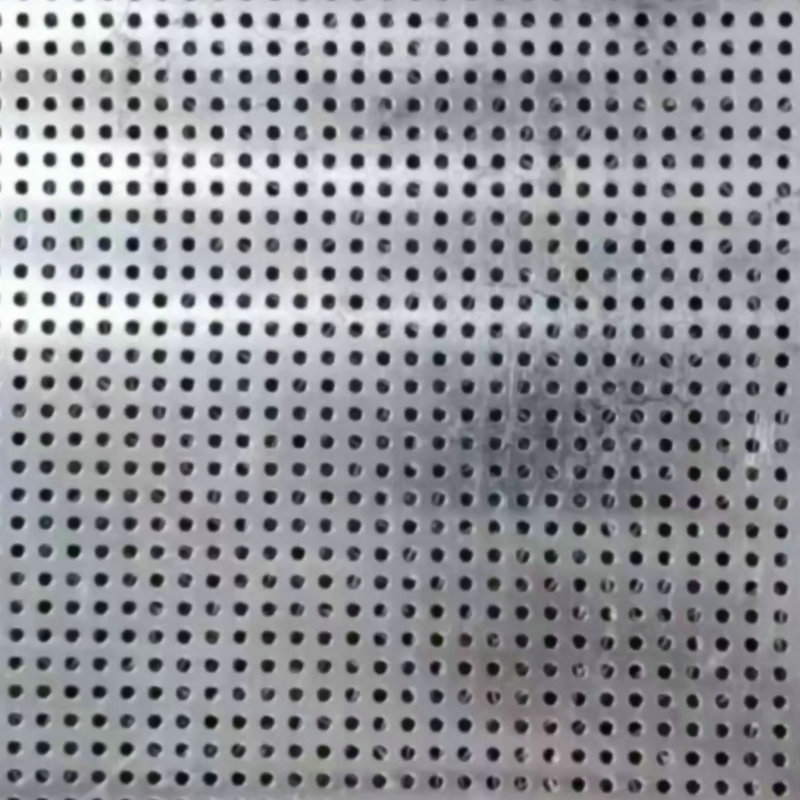

The diameter of the perforation is reduced to between 0.5mm-0.04mm on the 1.0mm thick aluminum plate. At the same time, its internal hollow geometric structure is utilized to achieve a better sound absorption effect. Thereby, eliminating other sound-absorbing porous materials attached to the back of the board.

| Product Type | Ultra Micro-Perforated Acoustic Panel |

| Product structure | 1.0mm Aluminum Plate+ aluminum hollow geometric structure+ 0.8mm Aluminum Plate |

| Standard Model | 0.4*0.04mm |

| Basic Material | Aluminum alloy |

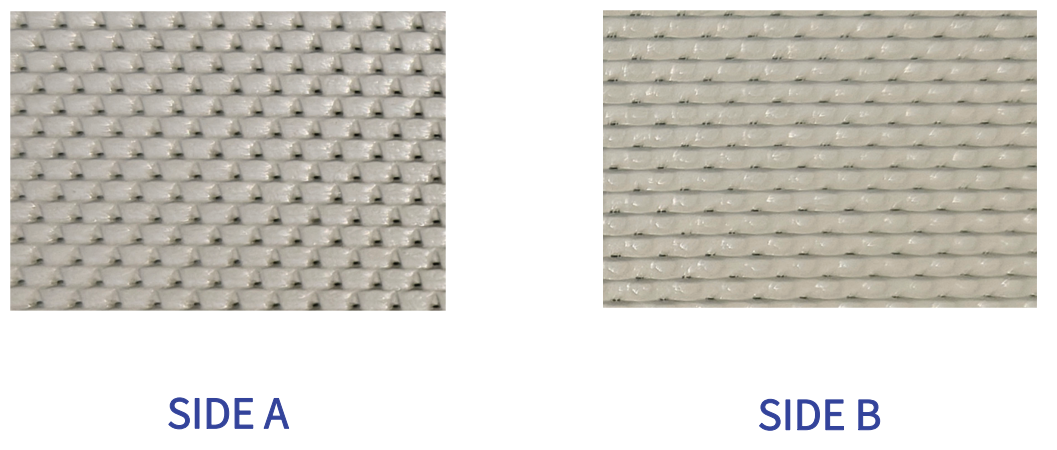

| Finish | Electrostatic powder coating, Wood grain thermal transfer, Anodizing (metal texture), UV printing etc. |

| Color | Color chart or customized |

| Size | width: normally less than 950mm

length:normally less than 3000mm |

| Thickness | 15mm or customized (Allowable tolerance:+-1mm) |

| Fireproof Grade | A grade |

Diameter of surface holes: 0.4×0.04mm

Ultra micro-perforated aluminum panel uses a patented angled micro-perforation method rather than traditional direct 90 punching methods. These perforated metal acoustic ceiling and wall panels feature an ideal surface to absorb wave energy generated by sound and electromagnetic waves, as well as for heat mitigation.

Diameter of holes: 2.5mm

Diameter of holes: 2.5mm

Distance of holes: E 5×5 mm

Auditoriums, bars, restaurants, conference halls, meeting rooms, open office areas, hotels, medical facilities, entertainment venues, retail stores, theaters, schools, convention centers, lobbies, swimming pools, laboratories, recording studios, gymnasiums, houses of worship, manufacturing and industrial facilities, music practice and band rooms, airports, etc.

info@buildingacustic.com